Wittmann Competence Days Hosts Variety of New Innovations in Auxillary Equipment

|

Getting your Trinity Audio player ready...

|

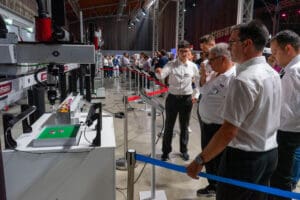

The Wittmann Group’s recent competence days in Vienna (June 19/20) gave ample proof of the company’s continuing innovation in ancillary equipment for injection moulders – with particular emphasis on further efficiencies in design, operations and energy savings.

The new Wittmann ancillary product launches include:

- The G-Max XL large-size blade granulator;

- The Drymax mobile materials dryer with EcoDrive,

- The ‘stand-alone’ version of the super-fast WX90 robot

- The direct current (DC) and solar-powered Tempro Plus, temperature controller

Over 1000 attendees were witness to these developments in Vienna and WIBA UK Joint MD Dan Williams led a party of thirty customers from all geographical areas to the event:

“Wittmann ancillaries are an essential part of our work in the UK,” he says. “A one-stop shop enables us to be truly solution-based for every injection moulding need. The unrivalled nature of our ancillary equipment can often open the door to customer interest in our moulding machines – and vica-versa.”

Joint WIBA UK Tracy Cadman adds that “all of our machinery innovation shows that Wittmann is also staying ahead of the curve when it comes to the circular economy: New designs such as the Gravimax with recyclate detection, the Feedmax Clean and various applications for our EcoDrive – these all mean that we are enabling our customers to win business through proven sustainable manufacturing.”

The WITTMANN Group is a globally leader in injection molding machines, robots and auxiliary equipment for processing a wide variety of plasticizable materials – both plastic and non-plastic.

Following the principles of environmental protection, conservation of resources and circular economy, the company’s mission is the production of state-of-the-art process technology for maximum energy efficiency – processing polymers and materials with a high content of recyclates and renewable raw materials.

All Wittmann products of are designed for horizontal and vertical integration into a Smart Factory and can be interlinked to form an intelligent production cell.

Read more from Wittmann Battenfeld here.

Wittmann Battenfeld UK

01933 275777

Website

Email