PlastikCity on Tour – Special Edition at KraussMaffei’s New Headquarters in Parsdorf

|

Getting your Trinity Audio player ready...

|

Welcome to a special edition of PlastikCity on Tour! In this exclusive feature, Jess Clarke and Will Clarke from PlastikCity ventured beyond the UK to the outskirts of Munich, Germany, where we visited the newly inaugurated headquarters of KraussMaffei—a titan in plastics processing machinery.

As invited guests, we had the privilege of exploring KraussMaffei’s brand-new, purpose-built facility, witnessing firsthand the cutting-edge technologies and innovative solutions that define the world of plastics processing and advanced engineering, along with KraussMaffei’s rich engineering heritage. Following the tour, we were also treated to an exclusive interview with Jörg Stech, Head of Injection Moulding Machines and chairman of the Management Board of KraussMaffei Technologies GmbH.

KraussMaffei: Pioneering a New Chapter in Parsdorf

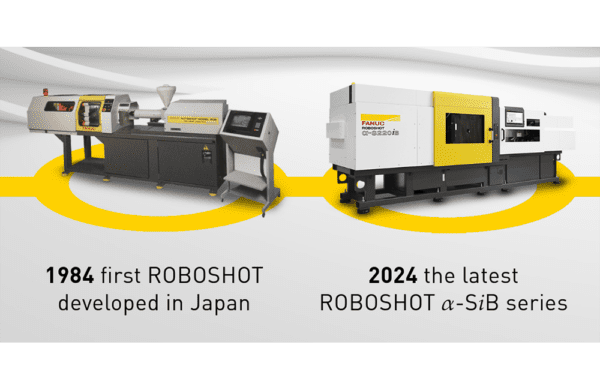

KraussMaffei‘s storied history is deeply rooted in heavy engineering, a legacy that began in 1838 with the manufacturing of locomotives. This foundational experience laid the groundwork for KraussMaffei’s mastery in precision engineering and complex machinery construction. This proficiency naturally evolved, allowing KraussMaffei to transition seamlessly into becoming a global leader in manufacturing plastics processing machinery.

The skills and technological expertise inherited from their early days in locomotive production have provided the company with a unique capability to handle the intricate demands of modern manufacturing technologies. Today, KraussMaffei is celebrated not only for its innovative solutions in plastic and rubber processing, but also for a longstanding tradition of engineering excellence that continues to shape its strategies and operations.

KraussMaffei has recently established its new headquarters in Parsdorf after almost 90 years in Munich’s Allach suburb. This move, which spanned across five years, represents the largest relocation projects in the company’s 185-year history. The new HQ is more than just a change of scenery; it embodies the latest in Smart Factory technologies and sustainable business practices. The Parsdorf facility is purpose-built and designed to meet the challenges of the 21st century, with a focus on increasing efficiency, embracing digital technologies, and fostering sustainability

A Beacon of Innovation and Sustainability

Upon arrival at the sprawling new campus, it becomes evident that KraussMaffei is steering the future of plastics manufacturing towards sustainability and efficiency. Led by Regional Sales Manager Peter Ils, Marketing Manager Petra Rehmet, and Head of Global Multi-Technology Projects René Dierkes, our tour began with an incredible view from the factory’s rooftop, showcasing not only the stunning panorama of the Alps but also highlighting the site’s extensive solar photovoltaic (PV) installation.

Recognised as one of the largest in Europe, this solar PV installation exemplifies KraussMaffei’s commitment to reducing its environmental impact and advancing sustainability in the plastics sector. With a huge 9.1 megawatts output, the power generated can power the whole factory on a sunny day!

The design of KraussMaffei’s purpose-built Parsdorf headquarters is nothing short of revolutionary. Every aspect of the facility has been meticulously planned to enhance workflow efficiency and reduce ecological footprints. From the strategic entry of raw materials to the streamlined exit of finished machinery and equipment and every other step in order along the way, the factory layout facilitates a seamless flow of operations, mirroring the company’s progressive vision.

Education and Training at the Core

KraussMaffei’s dedication to engineering innovation is paralleled by its commitment to education and training. The new HQ houses an impressive training centre that serves as a testament to the company’s role as one of Munich’s largest educational providers.

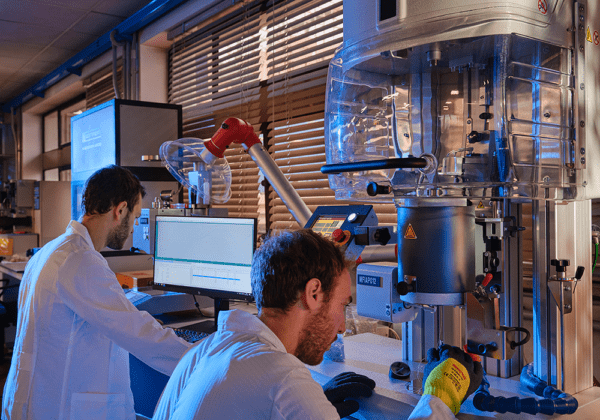

Equipped with cutting-edge virtual training technologies that reach learners globally, the centre features realistic workstations complete with KraussMaffei machine control panels, allowing trainees to experience hands-on learning from a classroom environment, as well as on the significant amount of production cells set up in the customer and training areas of the site.

Witnessing the significant investment in training, demonstration and trialling facilities for ourselves, it is clear that KraussMaffei values the education and training of its people in the highest regard. It was particularly noticeable during our tour of the site how many young apprentices and trainees, both male and female, were engaged with education and career progression within the company. It’s a testament to KraussMaffei’s principles that the company upskills and invests in its workforce, but also ensures that the wider industry benefits from well-trained professionals equipped to handle the complexities of modern plastics engineering.

Smart Factory: A Model of Modern Manufacturing

KraussMaffei’s Parsdorf site embodies the essence of a smart factory. The facility boasts three production halls, a main administrative building, four office buildings, two parking garages, a 15,000-square-metre Customer Experience Centre, and social areas including a cafeteria and a modern canteen that promote employee well-being and productivity.

Each element of the site has been designed to optimise energy use, from motion sensitive LED lighting systems to environmentally friendly heating and cooling systems that significantly lower the site’s carbon emissions.

The smart factory concept extends beyond physical infrastructure, touching every aspect of production and administration. Integrated digital systems streamline operations, from automated warehousing and advanced logistics, to real-time data analysis for operational decision-making. This digital backbone not only enhances production capabilities and efficiency, but also ensures that the facility can adapt to future technological advancements and market demands.

Leading the Way in Customer Experience

Perhaps the most striking feature of the new headquarters is the 15,000-square-metre Customer Experience Centre. This facility allows visitors to immerse themselves in the world of KraussMaffei, featuring live demonstrations and interactive displays of the company’s comprehensive machinery range, which includes injection moulding machines, extrusion technology, reaction process machinery, and additive manufacturing equipment. Here, customers can explore tailored solutions and witness firsthand the precision and engineering excellence that KraussMaffei machines offer.

The Customer Experience centre is also home to the Tech Centre, where new applications are developed and tested, a Final Inspection Centre for ensuring engineering quality, and a training area for digital products. This space not only serves as a hub for showcasing technological advancements but also facilitates a deeper understanding and collaboration between KraussMaffei and its global customer base.

As we concluded our eye-opening tour, it was clear that KraussMaffei’s investment in this new Parsdorf HQ goes far beyond mere physical expansion — it is a commitment to leading the plastics processing industry towards a more efficient, sustainable, and innovative future.

Exploring Innovations: An Interview with Jörg Stech

With the inspiring and fascinating factory tour fresh in our minds, we were privileged to be joined by Jörg Stech, Head of Injection Moulding Machines and Chairman of the Management Board at KraussMaffei. In this world-exclusive interview, Jörg offered deep insights into the company’s strategy, its commitment to sustainability, and its forward-thinking approach to serving the plastic manufacturing sector.

PlastikMedia: Jörg, this new facility is quite a step forward. Can you describe what this move means for KraussMaffei and its customers?

Jörg Stech: “Absolutely, we consider this site to be the most modern manufacturing facility for injection moulding machines globally. More than just a production site, it’s a representation of our evolution from a machine manufacturer to a solution provider. This shift allows KraussMaffei to more easily deliver comprehensive customised solutions that significantly distinguish us in the market.”

PlastikMedia: That’s quite an innovative approach. How does this philosophy enhance the customer and employee experience here?

Jörg Stech: “Our approach is very much about interaction and experience. We’ve dedicated a significant portion of our space here to our Customer Experience Centre. It’s designed to not just showcase our technology but to demonstrate it in action. This allows our customers to witness the capabilities of our solutions first-hand, ensuring they see the value and versatility of our offerings in real scenarios. Equally, we are focused on the well-being and professional growth of our employees. The improved workflow and reduced manufacturing costs at this facility reflect our focus of enhancing both customer satisfaction and employee engagement.

“For our customers, the investment in this new site means we can increase efficiencies, ultimately reducing lead times, but it’s more than just that. We can more easily store raw materials, manage stock, improve our workflow. All core machinery components are now made in-house, meaning we have a level of control and customisation that is unmatched.

“These are not the kinds of solutions you can get from anywhere – you need a dedicated supplier you can rely on. KraussMaffei is well-known for manufacturing the best plasticising unit you can possibly buy, which is produced here, with all of the know-how we’ve been developing over previous decades. Now we have the latest machinery to support and further grow with that technology and we have a clear dedication to work on this further in the coming years.”

PlastikMedia: You mentioned a shift from machinery supplier to solution provider. Can you elaborate on this? What makes KraussMaffei unique in this regard?

Jörg Stech: “Yes, I believe this is our unique strength, and a key advantage of KraussMaffei. We have experience in almost all areas of plastics processing, not simply the injection moulding machine. We present full solutions, including a moulding machine but also much more than that.

“We can deliver complex solutions for individual customer projects, using our experience and technical ability across a wide range of processes, including injection moulding, extrusion, reaction process machinery, additive manufacturing and automation. Using this experience, we design and deliver complete systems for complex projects from a single point of contact for our customers and I believe this is the big benefit of KraussMaffei.”

“The best examples for these synergies within our technologies are ColorForm or DCIM. With ColorForm a basic thermoplastic carrier is flow-coated with polyurethane in the second cycle. This provides an exceptionally high-quality, scratch-resistant surface. DCIM stands for Direct Compounding Injection Moulding and combines Compounding and Injection Moulding in one single process. Material savings of up to 50 percent per kilogram can thus be achieved – a further benefit in terms of sustainability.”

PlastikMedia: We noticed on the factory tour you have a lot of young trainees and apprentices working and training on-site. We often talk about skills gaps and struggling to engage young people in the UK industry – is that the same in Germany? Is this a concern for you?

Jörg Stech: “Yes, it is a huge concern. I would say this is the number one topic of concern within industry in Germany. We are fortunate in Germany to have a dual education system, allowing students to integrate with industry which has been very successful, we’re training lots of very highly skilled engineers, but there still isn’t enough for the whole industry – let’s put it that way.

“Of course, the educational levels required are always increasing too. It’s not just mechanical engineering skills on the shop floor we need today; we need these skilled people but today they need to know more, they need to know how to use digital tools for example, and this culture is constantly changing. With an excess of demand, these skilled employees can be picky about the company or role they choose, so we also need to be an attractive employer to get the best young talent.”

PlastikMedia: A new site like this must help with that, I imagine?

Jörg Stech: “Yes, of course. The factory is designed to benefit our employees, to create an efficient and enjoyable place to work, so lots of thought has gone into making this a great place to come to work. Also, the knowledge and history of KraussMaffei stretches 185 years, now 186 years. I hope young people passing our building will see our name and understand the history we have in this region.

“We’re very fortunate to have many skilled employees that have stayed with us for a very long time, which is just as important as attracting new young talents. I’m sure all will benefit from the new and modern environment we have now in Parsdorf.”

PlastikMedia: Sustainability is a critical global theme. How has KraussMaffei integrated this into the new headquarters?

Jörg Stech: “Sustainability is integral to our operations here. We’ve equipped the site with advanced energy-saving technologies and one of the largest solar power installations in Europe. These efforts are about reducing our environmental impact while also optimising our operational efficiencies. It’s essential for us to lead by example in sustainability within the industry.

“However, when talking about the contribution to sustainability of KraussMaffei, it’s not just about the site. The biggest contribution by KraussMaffei is our machines which help to recycle the material that already exists on the planet, so we don’t need to produce too much more. We can deliver across the entire recycling value chain, from raw material to finished product, and back again.

“We are delivering the full circle of the circular economy, and our customers rely on our knowledge and guidance to achieve their sustainability goals.

“We have done a lot of work in the automotive industry recently for example, because of upcoming EU recycling regulations, which are a huge driver of change within the sector. With goals to be met in the 2030’s, we are engaging closely with OEMs to provide guidance and solutions for these needs, across a wide range of machine technologies. I think this is KraussMaffei’s greatest contribution to sustainability.”

PlastikMedia: With the industry evolving so rapidly, how do you ensure that KraussMaffei remains at the forefront?

Jörg Stech: “Innovation is at our core. We are continually enhancing our facilities and systems to adapt to future demands. This includes significant investments in digitalisation and data management which will enable us to stay ahead of technological advances and respond proactively to market needs.”

PlastikMedia: Could you expand on how digitalisation plays into your strategic plans?

Jörg Stech: “Digitalisation is crucial for efficiency and scalability. By integrating advanced digital systems, we’re not only improving our production capabilities but also enhancing our design and development processes. This allows us to create more precise and adaptable solutions for our clients, tailored to their specific needs.

“We have invested a lot over recent years in our digital products, and now we’re able to offer complete training and onboarding from our on-site training centre. These digital products are also growing in importance and can help other efforts such as sustainability or efficiency. Our APCplus for example is a patented digital solution which helps running all types of material but also keeping the quality stable, which helps greatly for processing recycled material grades.”

PlastikMedia: What should your customers and the industry expect from KraussMaffei in the coming years?

Jörg Stech: “Our customers can expect a partner that not only understands their current needs but also anticipates future challenges. With our comprehensive approach incorporating everything from initial machine design to final production solutions including automation and process optimisation, we’re prepared to lead the way in the industry’s evolution.

“We continue to attract and retain highly skilled employees who bring decades of experience in almost all areas of plastics processing such as injection moulding. It’s essential for us to blend this seasoned expertise with fresh talent, ensuring that we continue to innovate and lead.”

PlastikMedia: Jörg, as we look towards the future, how do you view the challenges and opportunities that lie ahead?

Jörg Stech: “The industry is at a critical juncture with significant challenges such as sustainability and the need for technological integration. However, these are also immense opportunities. By embracing these challenges, we position ourselves to not only improve our operations but also to drive the industry forward. Our aim is to be at the forefront of the industry, setting standards in innovation, efficiency, and sustainability.”

As the interview concluded, it was clear that KraussMaffei is not just adapting to industry changes but is actively shaping the future of manufacturing. With a strong focus on providing comprehensive solutions and a commitment to sustainability, KraussMaffei is poised to remain a leader in the plastics and rubber processing industry for years to come.

This special edition of PlastikCity on Tour has provided us with an in-depth look at how traditional manufacturing can transform into a modern marvel, paving the way for others in the industry to follow. As we left the grounds, the view of the Alps in the distance served as a perfect metaphor for the heights that KraussMaffei aims to reach in its continued pursuit of excellence.