BMB to Showcase Packaging Prowess at Interplas 2021

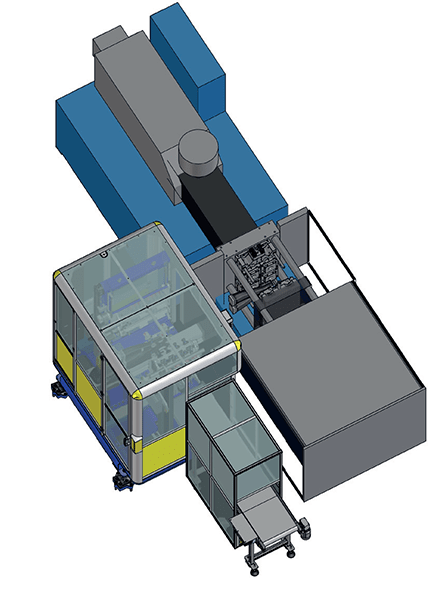

Leading manufacturer of high-tech injection moulding machines, BMB, will be exhibiting on stand D80 at Interplas 2021, taking place 28th – 30th September at the NEC, Birmingham. The team will be demonstrating a fully electric, high-performance injection moulding machine with an IML side-entry robot.

BMB’s machines are particularly well-known for their thin-wall container production, although they are also successful in automotive, medical and houseware industry due to the design flexibility of the machinery.

Due to the direct electric drives on the opening, closing, injection and plasticising phases, you can ensure that the overlapping movements are controlled with great precision, accuracy and, consequently, repeatability. Combining the reduced energy consumption of BMB’s unique direct electric drives with the use of recycled material suitable for food packaging, this application provides an exceptional example of eco-sustainability.

The main objective of this application is to improve the performance of the entire work cell, aiming at a constant production in excess of 2000 pieces per hour. At the same time, it limits production costs due to the electric drives for each movement of the machine and of the automation system. Incorporating a vision system, each product will be controlled in terms of quality and rejected in the case of an anomaly.

Additionally, the eKW 22Pi/700 full electric machine is equipped with a Mini-MODULA X-Series side robot, from Campetella. The robot is equipped with an extremely fast and compact horizontal arm. This guarantees the fastest operation of inserting the labels and extracting the finished product.

An oscillating arm ensures an efficient process orienting the cups in a correct stacking position. The entire system is a four-cavities application, with a total cycle time of no more than 2.6 seconds. The machine interlock time is only 0.6 seconds.

Visitors to the Interplas exhition can see all of this in action on BMB’s stand, D80, in Hall 4. Click here to register to attend.

BMB Plastics Machinery Limited

+44 (0) 7551 312685

Website

Email