The Impacts of UVC Sterilisation on your Products and Materials

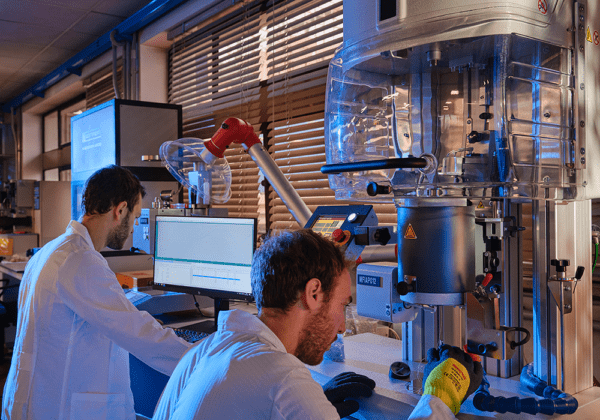

Radical Materials discusses the introduction of its latest piece of equipment, the Q-Lab QUV/uvc Accelerated Weathering Tester, and the importance of testing materials against UVC radiation.

UVC radiation has been used for many years to disinfect water supplies, pharmaceutical products and general surfaces, to name a few examples. The method is termed ultraviolet germicidal irradiation or UVGI. In recent times, there has been and will likely further be a dramatic increase in the use of such technology in areas such as transportation, retail, food processing and healthcare, with the aim of killing or inactivating bacteria and viruses on a wide range of products and materials. This is a marked change to the operating conditions of such products and materials and one which would rarely have been considered during original product specifications and developments.

Many materials used in such applications are not designed to withstand UVC, which is higher in energy than UVA or UVB and not present in natural light due to it being filtered by the ozone layer. UVC exposure can potentially lead to significant material degradation if not designed for and the speed and extent of this degradation is still largely unexplored, as well as the doses received in-service being extremely unpredictable. Unfortunately, standard UVA/UVB weathering tests will tell a manufacturer or user very little about the effect of UVC on a particular material. It can be a huge challenge to determine whether a material is fit-for-purpose based upon its degradation over repeated UVC exposure cycles.

As well as being able to offer solutions to improve resistance to UVC, Radical Materials now has the capability to expose a wide range of materials to controlled UVC cycles and analyse the impact of such cycles on performance parameters. The new Q-Lab QUV/uvc is specifically designed for UVC testing and precisely controls irradiance at 254nm to allow accurate exposure to pre-defined UVC dosage levels. UVC testing is still not well standardised but, with the correct application data, cycles can be designed to estimate exposures based upon dosage per cycle and expected cycles per service life of the product.

If you would like to discuss enhancing UVC resistance of materials or need to design for UVC exposure by better understanding the effect of specific repeated cycles on the performance of a material, then use the contact details listed below to get in touch with the experts at Radical Materials.

Visit the Radical Materials website to learn more about its other in-house manufacturing and testing capabilities.

Radical Materials is home to SteriTouch® antimicrobial, SCOPIC detectable, and Konduct thermal polymers.

Three brands, one RADICAL vision.

Radical Materials

01495 211400

Website

Email