Forteq UK Gears Up for Interplas 2021

Forteq UK is pleased to announce that it will be exhibiting on Stand B30 at Interplas, from 28-30 September at the National Exhibition Centre in Birmingham.

Forteq Group is a global injection moulder of technical components and assemblies to the automotive and industrial product sectors. Customers choose forteq to turn their ideas into tangible solutions and benefit from its expertise with engineering plastics. From its manufacturing plants in the USA, China, Czech Republic, Italy and the UK, forteq supplies precise and functional components to many of the automotive sector’s most well-known companies.

Forteq UK has been busy engineering three major new automotive projects that launch in Q4 2021, all for UK Tier 1 manufacturers.

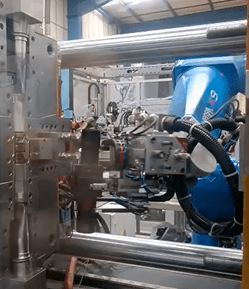

The projects have utilised a wide range of technologies such as automatic overmoulding of fine blanked metal inserts using a 6-axis robot, also heat insertion of threaded inserts with O-rings and leak testing of joints that have been ultrasonic welded and assembling fuel system valves to stringent cleanliness standards.

Many of the components have threads, male and female, with seal faces or need to meet customer aesthetic requirements. Advanced polymers have been used on seating components with high impact specifications and safety-critical characteristics, an example of metal to plastic aiding the light-weighting of vehicles.

Forteq UK has a 30-year track record of supplying gas, electric and water meter components to the industrial products sector. It recently won a new contract to produce precision plastic components for a gas meter valve that also commences in Q4 this year. The three components form a complex mechatronic assembly with tight flatness and roundness characteristics, along with a threaded seal carrier, clips and living hinge to minimise parts list and cost.

At its Huddersfield facility, fully automatic manufacturing cells with 6-axis robots and vision systems are used for technical overmoulded gear assemblies to give cost-effective solutions. The company produces high-volume components for wiper systems, door latches, window regulators, engine mounts, air suspension, geared actuators, power steering gears, timing tensioners, filtration, seating systems, HVAC and fluid delivery applications.

The advantage of choosing forteq UK is that it offers the complete package from concept to solution, thus enabling the production of consistent quality and tight tolerance parts in a lean manufacturing environment.

Forteq has in-house Moldflow and FEA capability, a vastly experienced engineering team, in-house and subcontract tooling options, and excellent quality and production teams that work 24/7. Additional technical processes comprise twin-shot moulding, ultrasonic welding, heat staking and leak testing.

Forteq has a technical knowledge bank of the latest moulding and joining technologies within-group globally, where sound advice can be offered to assist with the developmental stages of new projects.

Furthermore, Forteq UK is IATF 16949 – ISO 9001 – ISO 14001 accredited and a proud member of Investors in People.

Don’t forget to visit forteq UK on Stand B30 at Interplas later this month. Not already registered for Interplas? Click here to sign up for the event.

forteq UK

+44 (0) 1484 424384

Website

Email