BEC Group to Meet Demand for Automotive Filters with Latest Investment

New Milton-based BEC Group has invested in two BOY vertical injection moulding machines to meet the demand for a new automotive filtration product developed to reduce diesel emissions globally.

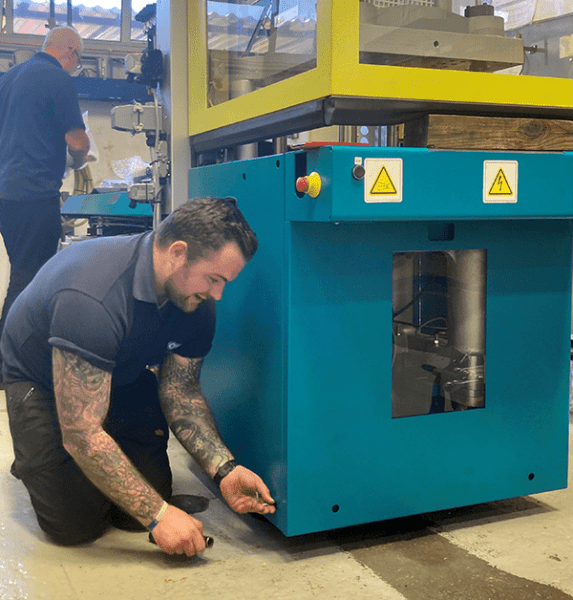

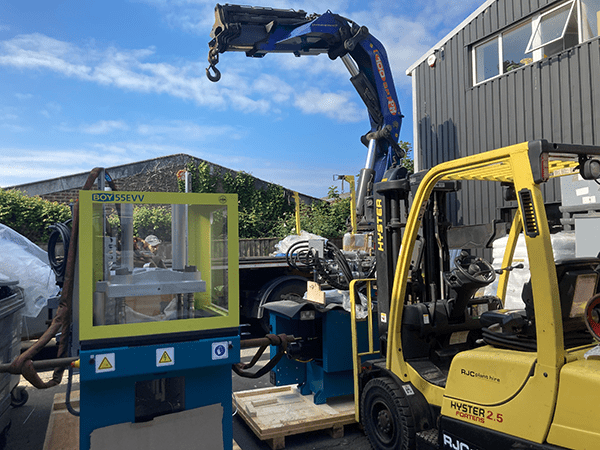

Both machines, the 55EVV and the 25EVV were delivered to the company last week to add to their existing plant list and increase capacity for their specialist filter overmoulding capabilities. The machines have been fully commissioned and are now in full production, manufacturing an expected one million of the new filters each year.

Holly Cummins, Sales and New Business Manager at BEC, said:

“Our new machines bring increased production capacity so we can easily meet the surge in demand for this new filter for the international automotive market. We’re also running a night shift, meaning more work for the team, which is great news.”

The diesel emissions fluid (DEF) filtration product, part of a year-long R&D collaboration project with their global leading customer, is the latest filter to add to the range. It plays a fundamental part in helping reduce diesel emissions, ensuring fuel systems in a wide range of vehicles – from trucks to the super-luxe – run more efficiently.

Paul Holland, Design and Innovation Manager at BEC, commented:

“These vertical moulding machines are a bit of a rare beast. We’ve certainly had a challenge getting them here, but it’s worth the wait. Seeing the project go from concept development all the way through to testing and now in full production from an engineering perspective is what it’s all about.”

Holly added:

“Knowing these specialist filters are making a huge difference is a massive achievement for a small independent company such as ourselves.”

Products that make a difference are in BEC’s DNA. Not least during the pandemic, which saw them making ‘the world’s safest visors’ for the NHS. They have also spent the last 20 years making filter encapsulated bottle caps to ensure the safe delivery of biological pests for use on crops worldwide.

These investments come on the back of two large machine purchases in 2020 as well as the upgrade of BEC’s IT system.

As BEC approaches its 43rd birthday, this signifies a promising future for all stakeholders, including the local community and another positive news story for UK manufacturing.

BEC Group

+44 (0)1425 613131

Website

Email