SCOPIC Additives Enable Detection of Polymer Foreign Bodies in Food

SCOPIC, part of Radical Materials, explores how metal detectable and X-ray detectable additives can be utilised within the food industry.

Foreign bodies entering the food processing chain and passing undetected through to consumers is clearly a major concern for the food industry. Examples of foreign bodies include metal, wood, ceramic, glass, rubbers and plastics. Due to the varying nature of these, often different detection techniques are necessary to target each. One of the most difficult categories to detect is rubbers and plastics (grouped together as polymers) due mainly to their comparative low density (similar to many foods) and non-conductive/non-magnetic nature. Polymers are used extensively throughout food production lines and hence being able to detect foreign body fragments of them is an important consideration.

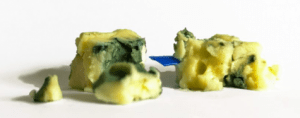

Early revisions of ‘detectable’ polymers relied purely on visual detection to prevent foreign body contamination. Polymer products were (and commonly still are) coloured blue to render them easier to detect on a food line due to the lack of naturally occurring blue in food products. Further enhancements lead to the introduction of modified polymers, detectable by conventional metal detection systems. This remains probably the most common format of detectable polymer.

Moving on from metal detection systems, X-ray detectors are becoming increasingly popular in the food industry. Compared to metal detection systems, they have the advantage that they primarily rely upon density differences to food products and hence are able to detect a range of additional foreign bodies such as glass, ceramic, bone, etc. With the growth in the popularity of X-ray, it is important to consider the suitability of this technique for the detection of polymer foreign bodies and the important points to take into account when doing so.

X-ray detection principally relies upon a differential in density (and atomic number) between the food product and foreign body, generating a detectable difference in absorption. The greater the difference in density between foreign body material and food products, the greater the detection sensitivity. A ‘typical’ value for the density of food products would be around 1.00g/cm3 (water). Due to the make-up of most polymers and the fact that many utilised on a food production line have a density below 1.30g/cm3 (polyethylene and polypropylene and below 1.00g/cm3), this differential is typically not sufficient to allow reliable and repeatable detection of standard polymer foreign bodies.

It is common to simply assume a metal detectable polymer will also show good X-ray detectability. Indeed, ‘standard’ metal detectable polymers will show an increased level of X-ray detectability over the unfilled polymer due to the increase in density caused by the additive. However, this is by no means optimised and good design of a polymer for X-ray detectability requires a special focus and numerous factors to be considered. These would include the design of the additive system, the base polymer utilised, minimum thickness to be detected, and all details of the food product(s) in the processing line (density and consistency, size and orientation, nature of containment material, etc).

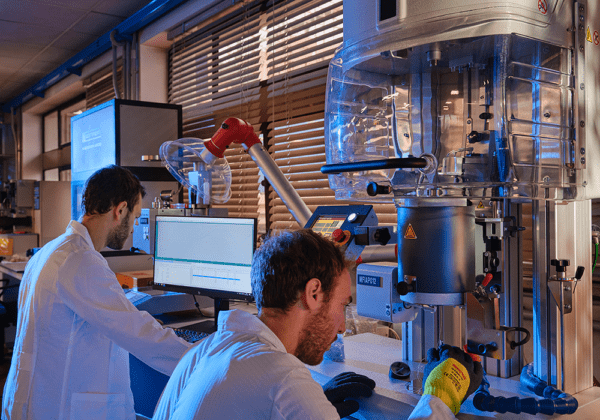

Radical Materials, through the SCOPIC brand, develop and manufacture polymer compounds and masterbatches with a specific focus on the detection technique being employed and can therefore supply solutions that are optimised for X-ray detection either in isolation or in combination with metal detection in dual systems. Using the in-house Minebea X-ray detection system, levels of detection can be shown and reported using closely replicated fragment sizes and food products and optimisations made as necessary.

Even with the optimisation of detectable polymers utilised on a production line, it is important to fully understand the X-ray inspection system of choice and its limitations via strong links with the manufacturer. Detectable materials should always be verified on the specific line of interest, utilising the actual food products and detection system(s).

If you’d like to learn more about how SCOPIC can help you solve your X-ray and metal detectable challenges, visit www.scopic.com or get in touch with the team using the contact details below.

Radical Materials is home to SteriTouch antimicrobial, SCOPIC detectable, and KONDUCT thermal polymers.

Three brands, one RADICAL vision.

Radical Materials

01495 211400

Website

Email