New Liquid Additive Enables Processors To Get ‘Virgin-Like’ Properties From 100% Regrind

Physical property tests carried out by Riverdale Global in cooperation with a moulder of packaging containers has demonstrated that +Restore™ liquid additive is even more effective than was originally claimed for improving the performance of plastics regrind based on post-consumer waste.

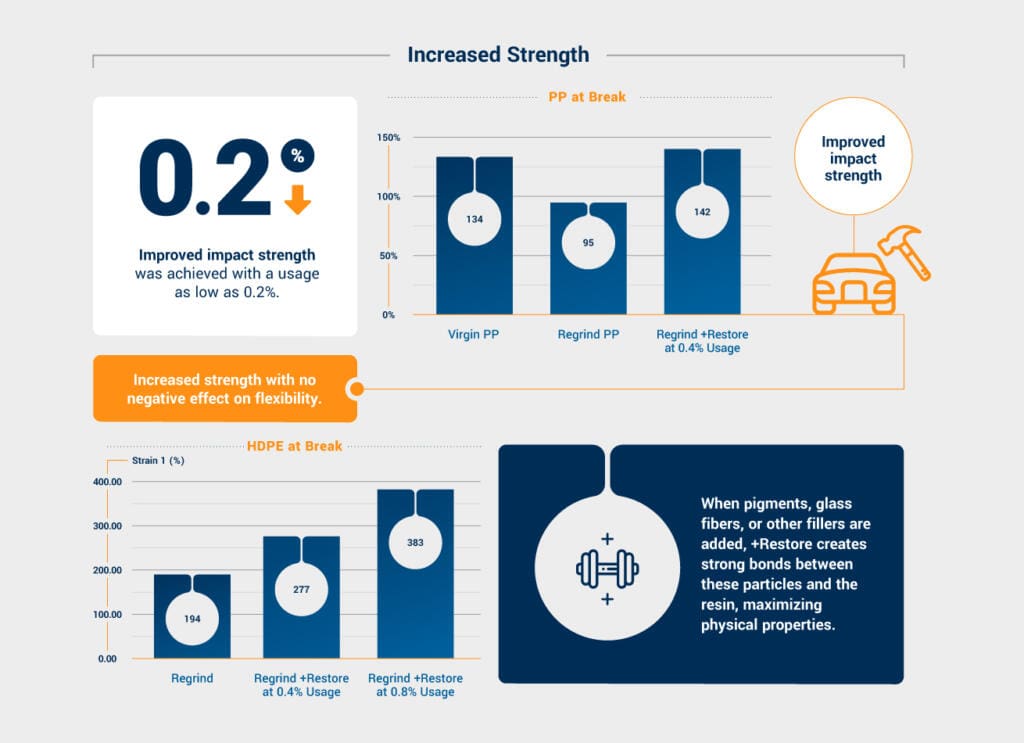

The test results indicate that at relatively low usage levels, the +Restore liquid additive enables processors running 100% post-consumer PP or HDPE to obtain products with virgin-like properties. Below are some test results comparing 100% virgin polypropylene with 100% PP regrind containing 0.4% +Restore additive:

- Flexural Modulus. Regrind PP tested at 99% of virgin PP.

- Strain at Yield. Regrind PP tested at 89% of virgin PP.

- Strain at Break. Regrind PP actually tested higher than virgin, at 106%.

- Izod Impact Strength. For regrind PP modified with +Restore additive, this property tested at 16% less than that of virgin PP, versus unmodified regrind at 49% less.

Jared Arbeter, Technical Sales Manager at Riverdale, said: “These test results and similarly encouraging data for HDPE show that plastics processors can use the +Restore additive to meet sustainability goals by actually upcycling post-consumer waste, eliminating most, and in some cases all, of the property losses typically incurred in recycling.”

+Restore also improves part consistency in comparison with untreated recycled material, Mr. Arbeter noted. As measured by standard deviation in a range of physical property tests, for example, HDPE regrind with 3% white concentrate exhibited 50% or more decreases in part variation when it contained 0.4% of the +Restore additive.

Other benefits are provided by the +Restore additive, according to Mr. Arbeter: “Because the additive has an affinity for the base polymer, it acts as a lubricant, enhancing melt flow. In addition, the +Restore molecule has a functional group that readily reacts with pigments, fibers, or fillers in the resin, while a different segment of the same molecule is designed to couple with the polymer; as a result, it forms a strong bond between resin and filler without compromising flexibility.”

The +Restore additive can be used in all thermoplastic processes, alone or in a blend with Riverdale Global’s liquid colors. Typical usage rates are in the 0.1 to 0.5% range.

Riverdale Global

01925 717321

Website

Email