HotSeat – Mark Dickin, Additive Manufacturing Manager at Ricoh 3D

Whether its removing tooling costs, slashing development time or achieving mass customisation, Ricoh 3D leverages additive manufacturing to save its customers time and money. Since joining the company in 1999 as a Technical Apprentice, Mark Dickin has risen through the ranks and now leads the 3D team as Additive Manufacturing Manager. Mark is the next PlastikCity Partner to face the HotSeat…

What trends do you think will shape the future of UK plastics? How will Ricoh 3D respond?

Firstly, I believe an increased awareness and adoption to move 3D printing from prototyping into series production will drive a greater range of applicable standards.

I also think that design for AM (additive manufacturing) will grow in importance. The majority of parts we receive currently could be manufactured via conventional methods, but manufacturers are not optimising the full range of benefits of additive manufacturing. Customers and use cases will ultimately drive further innovation – whether that be material, post-processing or design innovation, which we pride ourselves on being reactive to.

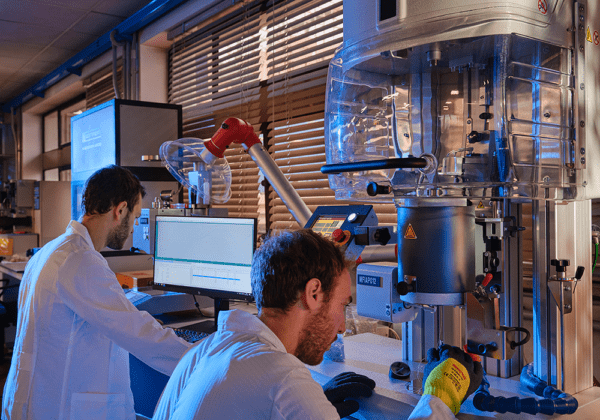

The range of polymer materials available for 3D printing is still limited compared to injection moulding. We expect this to change, as we continue to grow and innovate new finishing techniques. We’re in a position to integrate new materials quickly due to our range and diversity of technology. We benefit from five Ricoh SLS large-scale systems.

Sustainability is, of course, another huge topic. Businesses and end-users are becoming increasingly aware of the products they’re consuming and the waste they’re generating. There is a genuine drive for people wanting to change their habits for good, and any company that wants to survive has to be at the forefront of that. We’re seeing businesses move towards a ‘print on demand’ model, resulting in no need for storage costs or wastage of spare parts production.

How has Ricoh 3D developed during your tenure?

I was brought into Ricoh’s new UK 3D printing operation in 2017 to work on a one-off process engineering project, and I haven’t left since! I’ve moved the 3D operation from something that was an unknown within the organisation to something that is now widely supported globally.

Since then, we have brought injection moulding into the department to maximise the synergies between the two technologies and moved it from a small-scale service offering (which started with two engineers) to a commercial full-scale European operation.

We productionised the whole operation in line with Ricoh’s core business, introducing robust back-office systems and controlled processes. This culminating in the growth of our customer base by over 1000% across a range of industries including automotive, medical, industrial and consumer, by improving accessibility through our online instant quote and order platform.

What do you credit as the key to your success?

The trust in the Ricoh brand and the manufacturing heritage which we have worked to showcase and build on from day one. The infrastructure and investment of a large organisation have been vital, and we’re well supported from a board level and across the global network.

Having the right skills in the right roles is also essential. We’re a technically-led organisation and have a high level of technical skill in the department. Still, we recognised that we needed to bring in specific commercial skills to drive growth.

We also benefit from a wide range of ‘homegrown’ talent – long-serving engineers that have worked across several business areas, bringing their experience and skills to a new industry with the ability to offer our customers a complete manufacturing solution.

What has been the greatest challenge in your career?

I have a technically biased background so it was a great challenge for me to step into the commercial side of the business. I made sure to add specific commercial skillset into the team to support our development. In my opinion, a good leader empowers the team to deliver on their individual specialisms, rather than trying to know it all!

What advice do you wish you’d had on entering the industry and does that differ from the advice you would give to an apprentice joining now?

I would tell myself, and anyone else, to invest the time upfront in robust market research and data, to lower your business risks and set realistic goals upfront. This isn’t a one-off annual exercise either. Never think you’re an expert – the industry moves so fast, we all always have to be prepared to learn and innovate.

Now more than ever, I would tell an apprentice not to be intimidated by all the jargon, media hype and fast-moving pace of the 3D printing industry. So long as any apprentice has a good manufacturing and process background, these fundamental principles will always stand you in good stead. I came into a relevantly unknown industry as an engineer at heart. The commercial skillset does takes time to build but is essential to cut through, in what is an increasingly overcrowded marketplace.

What hidden talents do you have?

As a CrossFit junkie, I would have to say my handstand walk!

For more information about Ricoh 3D and how additive manufacturing can help transform your production processes, visit https://rapidfab.ricoh-europe.com/

![]()

Ricoh 3D

01604 814900

Website

Email