Can Machine Automation Help us Recover from the Pandemic?

During such uncertain times, investing may not be at the top of many companies’ agendas, but could Automation and Robotics be the key to helping many UK Manufacturing companies’ recovery plans for the future?

The current situation with regards to COVID-19 has highlighted a number of gaps for UK manufacturing companies in a range of industry sectors relating to disaster recovery plans. The virus has brought with it devastation, the likes of which have not been seen since the world wars.

Traditionally, UK manufacturing has seen a slow uptake introducing automated systems compared to the rest of Europe. Unfortunately, this has meant that a large number of UK Manufacturing companies will struggle to get back to full production due to having to put in additional safety measures to ensure COVID-19 provision guidelines are put in place.

With it being such uncertain times, investing may not be at the top of many company’s agendas. The downside of this is that for manufacturing companies, this may lead to the same outcome should a pandemic or other disaster strike again.

Should I Be Considering Automation?

Automation and Robotics could be the key to helping many UK manufacturing companies plan for the future. This should and probably will be part of many companies’ disaster recovery plans for moving forward, and hopefully, it will help us out of these unprecedented times. SP Automation and Robotics has been helping companies to improve on quality and output for many years. The benefits of automation have resulted in increased productivity and reduced labour costs. With the use of robots to automate, full bespoke automated production lines and flexible automation with built-in vision inspection and test equipment manufacturing processes can be improved to ensure optimum efficiency.

Who is SP Automation & Robotics?

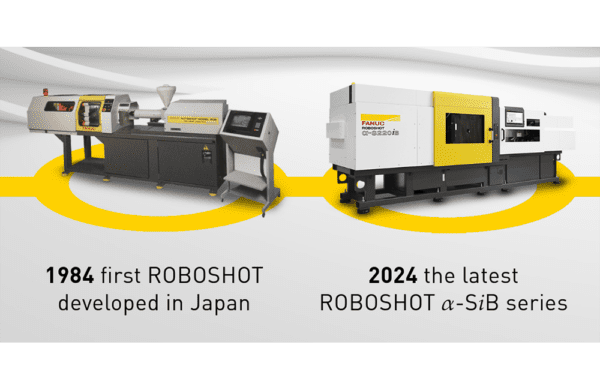

Established in 1984, SP Automation and Robotics has been at the forefront of designing and manufacturing custom-built automation solutions for many industries. Over the years, these industries have included medical device, defence, food and drink, and automotive to name but a few.

At the beginning of the year, we rebranded from SP Technology to SP Automation & Robotics. There were two main reasons behind this, the first being to give a meaning to our name and tell the story of what we do. The second was to align our new division, SP Elements. This division was established to concentrate on the lower cost and quick deployment of automation using collaborative robots. To ensure continuity, the SP (which stands for Special Purpose) was retained and remained at the core of our name and what we do.

What Types of Customers Do We Work With?

Clients ask this quite a lot, and the simple answer is that there is not a single type of customer. Each customer has their own set of unique problems and requirements. There are, however, several common traits that all our customers have. All of them are looking to improve efficiencies, production rates and product quality. The range of systems that we have produced over our 35 years are vast and have included full assembly of multipart assemblies, packaging and palletising, inspection, and material removal amongst many others.

Our Divisions

At the beginning of 2020, SP Automation and Robotics created another division called SP Elements. The new division was created to concentrate on the sales of collaborative robots. Our core business as SP Automation and Robotics is medium to large fully automated systems, which can range from £30k to £3,000,000 supplied into a myriad of industries from medical devices through to automotive. The idea behind SP Elements is to offer companies a cost-effective and practical entry to automation by offering elements of automation using collaborative robots (cobots).

The cobots are extremely simple to program and are suited to companies that have repetitive and sometimes laborious tasks and want to free up skilled workers to do what they are good at. Working directly next to humans, cobots can (after a risk assessment) operate unguarded. This makes redeploying cobots to carry out other operations within factories a simple process.

With regards to costs and return on investment, a cobot can potentially have a payback within eight months on a single shift, therefore, providing a very fast return on investment. To minimise outlay costs new leasing options available, so effectively the cobot can paying for itself as you spread the cost. These leasing options can also include any associated tooling. With regards to deliveries, a cobot can be delivered and up and running within three weeks.

“If you need a machine and don’t buy, eventually you will have paid for it, but won’t have it” – Henry Ford.

Over the coming months and years, manufacturers will be looking at ways to ensure they can react to disasters such as the COVID-19 situation. Considering automation now, can help them in the future. Automation does not have to big and fixed and expensive. It can also be simple and flexible and affordable by using collaborative robots. SP Automation and Robotics can service and support both ends of the spectrum and help manufacturing companies to become more competitive and help safeguard their future.

Podcast: SP Elements become Scotlands sole distributor of Universal Robots collaborative robot. Listen below:

Learn more about SP Elements and their Collaborative Robots here.

SP Automation & Robotics

01382 880088

Website