New Intouch i4 Cloud to be Showcased at K2019

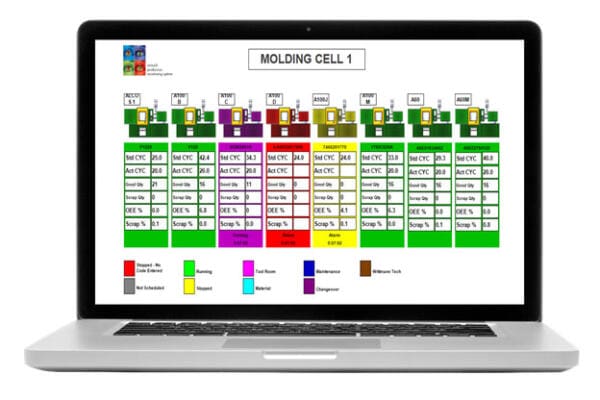

Intouch believes that all manufacturers should have the tools to make the best production decisions and has spent more than 20 years ensuring that their system gives users the visibility and control to make decisions that lead to significant improvements in OEE and profitability.

Intouch has now made it even easier to get up and running and with very little capital expenditure, by introducing Intouch i4 Cloud.

The Cloud system, which will be showcased at the K Show 2019, is the new subscription-based i4 system and provides the most common functionality of their on-premise system (Intouch i4 Custom) but can be accessed immediately via the internet, has a very low initial investment and easily scalable according to requirements. Support, updates and backups will be managed by Intouch, leaving you to concentrate on your core manufacturing business.

Implementation – 3 easy steps

1) Place your order – Hardware will be dispatched

2) Specify – Send us your specification, and we will build and configure your system

3) Switch on – Wire up to your machines and you are ready to start monitoring and saving. Training included in the subscription fee.

The revolutionary Cloud technology is responsible for the huge leaps in advances we are experiencing today. Companies worldwide are investing in the Cloud to capitalise on the best technology available, usually with significantly less capital expenditure. Customers who have implemented the new Intouch i4 Cloud are already reaping the benefits:

Plastics Parts Direct commented: ‘Since implementing the Intouch i4 Cloud, Monday morning start-up times have improved by 1 hour across all machines, cycle times have improved by 5-8%, uptime has been significantly improved and the real-time data has prompted us to buy a new machine and instantly we saw an increase of 30% in efficiency and cycle times and a reduction in power consumption too.’

Installed in over 300 sites worldwide, the Intouch real-time monitoring, scheduling, reporting and analytics system is suitable for a multitude of industries and processes including packaging, automotive, medical, aerospace, injection moulding, thermoforming, extrusion, printing, CNC cutting/machining, metal-stamping and food processing. Intouch systems are flexible and easy to use and integrate easily with ERP software.

Visit Intouch at K Show 2019 from 16th-23rd October, in Hall 5, Stand A25.

Intouch will also be monitoring the Romi machines at their stand (Hall 15, Stand D40), giving visitors the opportunity to see the Intouch system in action.

Intouch Monitoring

+44 (0) 1604 537100

Website

Email