ALBIS at K 2019: Less CO2, Greener Products, Safer Healthcare Applications, Digitisation

ALBIS will present a range of high-performance plastics, compound solutions and masterbatches at K 2019, the trade fair in Dusseldorf, Germany from October 16 to 23, 2019.

- ALBIS has expanded its portfolio of sustainable products: versatile solutions from one hand

- On October 15 the 5th ALBIS Healthcare Lounge will bring industry experts together

- Safer products with ‘medical-grade plastics’ via VDI guidelines

- ‘Digital business’ team analyses the brands and business processes of the future

As one of the world’s leading distributors and compounders of technical thermoplasts and thermoplastic elastomers, the Hamburg-based company will be showcasing products and exhibits by long-term partners like BASF, Covestro, INEOS Styrolution, LANXESS, LyondellBasell, EASTMAN and Solvay, as well as its own collection of complimentary ALBIS branded products.

Range of recycling and bio-based products expanded

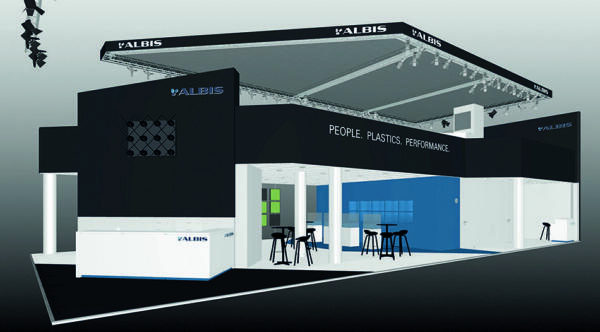

The focus of the two-story stand will be answers to the most important challenges of the day.

“Our customers want us to tell them how they can make their applications greener and more sustainable, without compromising on quality,” says Philip O. Krahn, ALBIS CEO. “We have, therefore, increased the proportion of recycled and bio-based products in our range.”

Some of these are LyondellBasell´s Circulen and Circulen Plus product families. They are low-density bio-based polypropylenes and polyethylenes with renewable hydrocarbon bases, recovered from sustainable bio-based resources such as used and residual oils. These are approved for use in the manufacture of food packaging.

Quality Circular Polymers (QCP™) post-consumer recycling products are part of LyondellBasell’s existing product families, Moplen® PP and Hostalen® PE, and are oriented towards high-quality applications, including cosmetics and suitcases.

While QCP products are made predominantly from packaging that has reached the end of its life-cycle, MGG Polymers products are made from PC+ABS, ABS, HIPS and PP granules that generally come from processed electrical and electronic waste (WEEE). In contrast, MBA Polymers UK produces post-consumer ABS, PP and HDPE from plastics rich shredder residue from recovered vehicles.

ALTECH® ECO deals with sustainable technical compounds that comprise up to 100 per cent high-quality post-industrial fibre and polymer raw materials. With their Near-to-Prime® quality and an excellent price-performance ratio, they meet the high standards required by the automotive and E&E sectors. Using 1kg ALTECH® ECO in place of virgin material saves the same amount of CO2 as used by a modern Golf type car travelling 100 km – a value that significantly reduces the CO2 footprint of the product’s entire value chain.

Another trade fair highlight will be the carbon fibre based compounds products by ALBIS subsidiary WIPAG. WIC-PP and WIC-PA products feature excellent rigidity, pressure and tensile strength, yet have low density, which saves a great deal of weight, and therefore expense, compared to highly filled fibreglass-reinforced PA types – ideal for all types of lightweight construction. In addition, the material is very dimensionally stable, has interesting electrical properties and has very good friction and wear properties. The valuable fibres are sourced on a large scale from offcuts from the manufacture of lightweight carbon fiber components in the aviation industry, wind turbines, and the automotive industry. WIPAG has developed the recycling technology required and scaled it up in order to be able to produce WIC compounds from this resource base.

With the environment and the reuse of valuable material in mind, LANXESS also offers thermoplastics with recycled elements. Durethan® ECO is a flame-retardant thermoplastic reinforced with 20 % glass fibre which has a recycled element as a sustainable resource. The polyester blends in the Pocan® ECO range contain a specially treated post-consumer PET as the blend partner. This makes it possible to manufacture premium finished parts, e.g. in the white goods sector, with properties and quality levels that are almost indistinguishable from those made with virgin materials.

BASF Ultramid® S Balance is characterised by high rigidity, thermal resistance and mechanical fixity thanks to a particularly high chemical resistance and low moisture absorption. BASF Ultramid® S Balance is particularly favoured for use in components that have media contact; the base polymer is made in part from renewable resources and so is classed as a bio-based product.

EASTMAN TREVA™ is another cellulose-based technical bioplastic that offers both high performance and low environmental impact. TREVA is chemically resistant, dimensionally stable and has excellent flow. It is BPA free and produces an exceptional depth of colour and high gloss for opaque applications.

Then there is Cellidor®, a plastic made from cellulose from sustainable natural resources, with a brilliant depth of colour and high impact resistance. The special things about this classic material are its unique feel and its scratch resistance due to its “self-healing powers”.

TECNARO also offers compounds made from renewable resources. These compounds are distinctive for the way they combine renewable raw materials and industrial compostable raw materials and are used for a variety of different applications.

Medical-grade plastics in line with VDI guidelines ensure customer safety

With ALCOM® MED, ALBIS has expanded its product portfolio to include tailor-made compounds for health care applications such as medical products, pharmaceutical packaging, and diagnostic applications. These products are based on a variety of different polymers and include pigmentation as well as a wide range of fillers.

“We are seeing a continuously growing demand from the processing industry for compounds that both comply with the regulatory requirements and offer customer-specific material solutions,” says Mike Freudenstein, Director of Marketing Healthcare at ALBIS. “ALCOM® MED means we can guarantee our customers’ production with strict quality criteria and offer close project support through our experienced healthcare specialists.”

Besides focusing on the technical features of its products, ALBIS is also emphasising service aspects like consistent formulas, dedicated change management, and regulatory support, for example as regards biological evaluations of materials.

These are consistent with the recently agreed “VDI 2017” guidelines. ALBIS, along with reputable experts from the medical and pharmaceutical sectors, and large globally active plastics manufacturers, was significantly involved in drawing up these guidelines. They define and describe what should be understood by the term medical grade plastics and which properties and requirements are significant for plastics that are to be used in medical products. They assist raw material manufacturers and producers to create plastic products with consistent formula, quality, biocompatibility and supply security.

“We are proud to be part of the initiative. It increases the safety of healthcare products and helps to prevent user complaints,” says Freudenstein.

The latest developments in the healthcare sector will be discussed at the 5th ALBIS Healthcare Lounge on October 15, 2019 (10 am – 6 pm, Hotel Melia, Inselstraße 2). On the agenda will be presentations by a leading global polymer manufacturer, information about “medical-grade plastics”, current developments around the regulations for medical devices (MDR) and interesting facts about sterilisation in the healthcare sector. Participants will benefit from networking opportunities at the post-event get together and the joint dinner. Registration can be done via healthcare@albis.com.

Opportunities to integrate with digitisation and industry 4.0

Which channels and technologies will we use to communicate with our customers and stakeholders in the future? What will the market, logistics and production of the future look like?

“In the future markets will operate differently and our aim is to be at the forefront of these developments rather than running to catch up,” says CEO Philip O. Krahn. “To this end, we set up a digitisation team early on and are already in the test phase of various projects with our partners and customers.”

“We are also testing digital platforms, distribution channels and smart factory,” says Matthias Schulz, Head of Team Digital Business. “It is important for us to be in constant communication with our partners and customers and to develop in a targeted and cooperative way.”

Tailor-made solutions and service from one hand

“K is the biggest international industry trade fair, and every time it is a great opportunity for us to meet and network with customers, partners, colleagues, media representatives and friends,” says CEO Krahn. “At our stand, we will present and demonstrate our cross-industry solutions and services. This comprehensive selection of products will help us make good on our promise to deliver the perfect solutions every time for our customers’ specific needs.”

ALBIS PLASTIC profile in brief

ALBIS PLASTIC is one of the leading globally operating companies in the distribution and compounding of technical thermoplastics and thermoplastic elastomers. In addition to the product portfolio of well-known plastic manufacturers, ALBIS offers the plastic processing industry a diverse product range of high-performance plastics, compound solutions and masterbatches. In 2018, the ALBIS Group, which has more than 1400 employees, achieved sales of 1.1 billion EUR. With 26 locations worldwide, the Hamburg based company is strongly represented in Europe with a growing presence in North Africa, the Asia Pacific and the Americas. At five German locations as well as in Knutsford (UK), Duncan, South Carolina (USA) and Changshu (China), ALBIS produces compounds and masterbatches, in part specialising in high-quality recycled compounds and green materials. All sites are certified according to the IATF 16949 or ISO 9001 Standard. In 2018, ALBIS was certified according to European Corporate Social Responsibility standards by rating specialist EcoVadis.

For more information, visit http://www.albis.com and http://www.albisamericas.com.

Visit Albis at K 2019 in Hall 8-B3, Stand A61.