Digital Pioneers Present World Premiere at K Trade Show

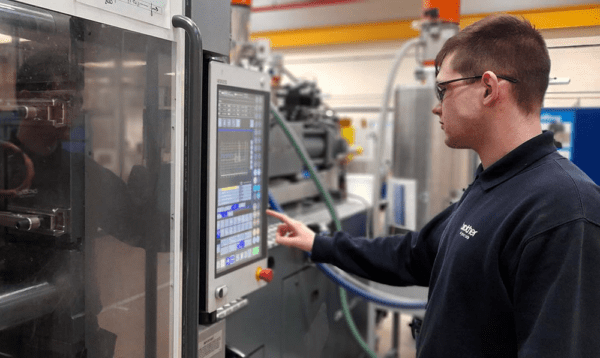

Can operators make injection moulding machines fit for Industry 4.0 if they are decades-old yet still reliable? Yes! KraussMaffei is presenting a world’s first at the K 2019 trade show.

-

- The Digital & Service Solutions (DSS) business unit offers digital services for all machine generations and plastics processing technologies

- Live presentation of an existing machine featuring a digital retrofit

- Data analysis as a service

- Social Production: Communication between machines, personnel and software for a proactive strategy

As of now, various bundles enable the networking and use of data for all machine generations and makes in the area of Injection Molding. Soon, Reaction Process Machinery and Extrusion Technology will also be integrated into the common data ecosystem. This makes KraussMaffei the digital forerunner.

Industrial Internet of Things (IIoT) as the basis for retrofitting

What’s the best way to digitally standardise organically grown production facilities and efficiently equip them for the future? With the new retrofit program, KraussMaffei creates the technical prerequisite for connectivity—across processes, generations and, going forward, even across manufacturers. These, as well as the IIoT, form the basis for the use of cloud-based products and services. Wherever data arises, it also needs to be stored. This can take place entirely in the cloud via a gateway computer, or near-network using Edge computing—depending on the existing IT environment, the volume of data that accrues and personal preference. Advantages for the customer include quality improvement, production control, and greater efficiency thanks to the reduction of maintenance, energy, material and personnel costs. Experts agree that in the future, businesses will be competitive only if they have a networked system of production.

DataXplorer for all technologies

Today, KraussMaffei already commands innovative tools such as the DataXplorer, which stores up to 500 signals per second as continuous curves, shedding light on processes in their entire depth. These signals can originate from the most diverse sources: from the machine itself (such as temperatures and positions of the clamping unit or the screw), from the mould (e.g. cavity pressure), or from peripherals, such as a milling cell that post-produces lightweight components from thermoset. The DataXplorer opens the door to status and process monitoring for Injection Molding, Extrusion and Reaction Process Machinery in equal measure.

Condition Monitoring – identifying errors before they occur

Using alarm and threshold values, the machine operator can be informed of relevant deviations in product parameters in a timely manner—by means of the dashboard in the master control station or by smartphone. Predictive Maintenance, or condition-based monitoring, then prevents unexpected production failures as a result of wear and tear on components. Similarly, rejection rates—such as those caused by shot weight deviations—drop.

Social Production – all of the production, always in view

Machines and personnel can only behave proactively if they can communicate with each other in real time while being supported by intelligent software. This makes it possible to prevent potential problems in the production sequence at an early stage. The new KraussMaffei App, Social Production, can be of assistance here. It uses the advantages of social media for a completely new type of production monitoring. The patent-pending process identifies process disturbances autonomously based on underlying data, without any user configuration, and provides tips on possible solutions for troubles. The system is compatible with all commercially available injection moulding machines.

Further devices within the production cell are expected to follow. KraussMaffei uses its decades of experience in the market to provide solutions for the special requirements of the plastics industry. The industrial messenger function of Social Production is intended to replace messenger programs such as WhatsApp or WeChat, which are used mostly in a semi-official capacity. Social Production simplifies and accelerates communication in production and makes collaborating with colleagues more efficient.

Because some companies do not want to concern themselves with data analysis and similar areas for their production, DSS offers the option to outsource specific analysis knowledge with the slogan “We help to unlock the value of your data”. Using the information that is available, experts will help to achieve the best possible process optimisation, generate customer-specific reports and provide data-driven guidance for decisions. Experts provide customised, high-resolution process data analysis that helps you identify the right actions to take and implement them — a small investment with maximum impact.

Polymore – KraussMaffei’s digital marketplace

A digital product of a completely different type is also waiting in the wings. Polymore is a new B2B online marketplace for the procurement and sale of compounds, masterbatches, recycled materials and post-industrial materials in Europe. Since sustainability is on society’s mind more than ever before, the use of recycled materials is also moving to the forefront. Polymore connects compounders and plastic processors for simple and secure trade in products. Together, they provide sustainable value creation with added value on both sides.

Thanks to the consistent focus on new, digital products and services, which can also be customised as packages for customers, KraussMaffei is aligned towards current and future market and customer requirements. The DSS business unit unites the expertise of three core technologies in plastics processing with its best-in-class machines and software engineers as well as data specialists and IIoT specialists. This provides maximum impact for networking machines and processes to each other. The digital pioneers present new paths of digitalisation for KraussMaffei.

Visit KraussMaffei at K Show 2019: Hall 15, Booth C24-C27

KraussMaffei

+44 (0) 1925 644100

Website

Email