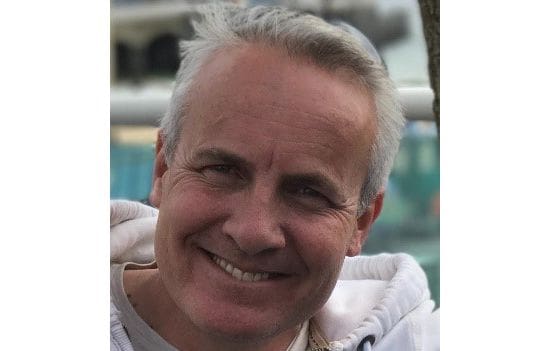

HotSeat – Sean Downey, Business Development Manager at Agentdraw

Agentdraw is a leading manufacturing company within the UK plastics industry, specialising in the production of injection moulded components. Business Development Manager Sean Downey has been with the company for a year now, with over 30 years’ experience in the industry and particular expertise in automotive. He is the next PlastikCity Partner to face the HotSeat…

What trends do you think will shape the future of UK plastics? How will Agentdraw respond?

Plastics are playing increasingly more part in our growing need to build lighter stronger and cheaper products. Advances in polymers and manufacturing techniques allow designers to specify plastics in areas impossible to conceive 20 years ago. Predominantly the Automotive and Aerospace industries lead the advancement in utilised plastics and resins, and it’s exciting to see how this transcends across other sectors. With regard to manufacturing then automation is something almost every plastic injection moulder is looking to harness. With increases in the minimum wage, greater demand and emphasis on right-first-time quality, many manufacturers are increasing their levels of automation to improve output and remain competitive.

As a plastic injection moulder Agentdraw have always prided themselves on staying at the forefront of the industry, whether through the advancement of specialist polymers…yes, we are alchemists and develop our own blends or in taking on mind-bending challenges that our competitors simply walk away from. In fact, I would go as far as to say that the greater the challenge, the greater the smile on the face of our MD.

How has Agentdraw developed during your tenure?

I have only been with Agentdraw for 12 months but having worked for other plastic moulders, it’s refreshing to see a business that has truly embraced challenges and developed new manufacturing techniques. Even after 30 years, I had my eyes opened to some of the advancements this company has made, and for a sales guy, it’s like having a box of fine jewellery to present to new customers.

What do you credit as the key to your success?

I was schooled in the age of the Youth Training Scheme and believe the modern apprenticeship provides a fantastic opportunity for those wishing to push forward in the industry. Work hard and embrace every opportunity that presents itself and you will never look back. The right employer will recognise those standout students and coax them to reach their full potential. I was privileged to stay with my first employer for a further 14 years after my apprenticeship and worked all over the world. Speak to any modern-day CEO and 9/10 would have completed an apprenticeship…just a thought!

What has been the greatest challenge in your career?

Managing my first Automotive program. I worked for a leading restraints business who manufactured seat belts and were forefront at the advent of automotive airbags. I was in my early 20’s and dealing with customers who were older and far wiser than me…the lesson I learnt was to show respect, listen and a learn and only chirp in when you were 100% confident.

What advice do you wish you’d had on entering the industry and does that differ from the advice you would give to an apprentice joining now?

I think basic manners and once again showing respect for those who really know their stuff. Don’t be afraid to say you don’t know but will find out rather than trying to blag your way through, you’ll just show yourself up and also your employer. Being a little more worldly wise these days I still see younger guys with fresh degrees thinking they know more than the engineer who’s winding down to retirement. I’m 50 years old, and part ex’d my engineers’ hat for sales many years ago yet I still learn something from my colleagues every day.

What hidden talents do you have?

I surf, windsurf, kitesurf and model for a boutique clothing brand…God, I’ll never live this down!

Agentdraw

+44 (0)116 2841386

Website

Email