Get Intouch at PDM Stand D035

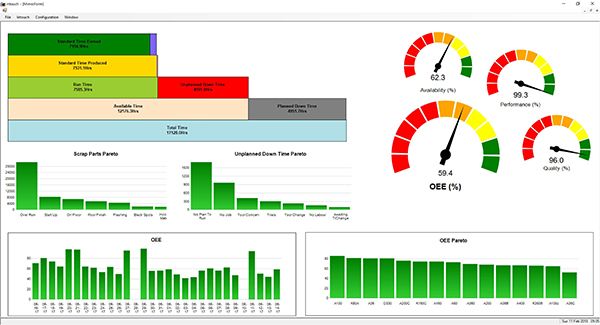

Intouch Monitoring becomes even smarter at PDM 2018 – delve deep into reports and make sense of your data with the new fully customisable, agile and flexible Intouch Manufacturing Execution System Intelligence (MESi) software.

Designed to be intuitively used; analytical dashboards and reports are easily built allowing users to better interpret problems, answer questions, uncover opportunities and make optimal business decisions.

Founded in 1997 by a production manager and an engineer, Intouch production and process monitoring, scheduling, reporting and analytics systems are installed in over 300 sites worldwide across a multitude of industries; from automotive and packaging to aerospace, horticulture, construction and medical. Customers have all reported significant improvements in productivity as well as other key benefits:

- More CAPACITY without more assets

Less downtime for more parts and less cost - Improve THROUGHPUT

Reveal and analyse loss – output speed/cycle-time/line rates - Improve quality/REDUCE SCRAP

Reveal quality losses and reasons - Improve Overall Equipment Effectiveness/Efficiency OEE

- Improve use of (direct & in-direct) labour – REDUCE COST

- Monitor energy consumption – LESS ENERGY USE

Visitors to the stand will also be able to experience Intouch’s new robust, high resolution and feature-rich User Interface (HMI) hardware choices. With wi-fi options and the ability to view centrally controlled videos and documentation at the machine/point of manufacture, Intouch makes it even easier to seamlessly connect the boardroom with both your local and global manufacturing shop-floor operations, enabling potential issues to be dealt with before they can become a costly problem.

Join the team on Stand D035 to discuss what the Intouch system can do for your business.

Intouch Monitoring

+44 (0) 1604 537100

Website

Email