ASTM D638 Tensile Testing of Plastics

Impact Solutions, through our laboratory, have extensive capabilities and experience in plastic testing. Our facility houses a mix of state of the art plastic testing equipment and bespoke designed plastic testing rigs allowing us to undertake a wide range of different test techniques on plastics. This includes ASTM D638 (technically equivalent to ISO 527 -1) is a testing standard which ascertains the tensile properties of a plastic material.

The test method can be used for testing materials up to 14mm (0.55 in.) and the material should be in the shape of a “dumbbell” or “dog bone”. If a material is thicker than 14mm then it must be reduced. However, if a sample is less than 1mm (0.04 in.) in thickness then it must be tested to standard ASTM D882, for example film or thin sheeting. The tensile properties of a material are the abilities of a material to resist deformation or breaking under tension. Although this blog is primarily focused on plastics, other materials such as metals and ceramics can be tested using tensile tests.

Testing Procedure

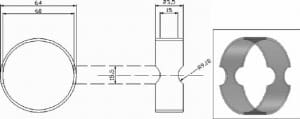

A sample of material will be cut or injection moulded into one of five required shapes, the “dumbbell” or “dog bone”. Each material will be slightly different depending on the thickness or toughness of the material.

Once the material has been specifically shaped and is ready for testing, it is loaded into tensile grips and an extensometer is attached (if contact extensometer is used) to the sample. The test begins as the aforementioned grips separate, pulling the sample from both ends at a constant rate of speed. The rate of speed can be altered depending again on the thickness or toughness of the chosen material/sample. This speed can range from 0.05 inches all the way through to 20 inches per minute this variant will influence the results. The test will usually last between 30 seconds to five minutes and ends when the material deforms, ruptures or breaks.

Measurements

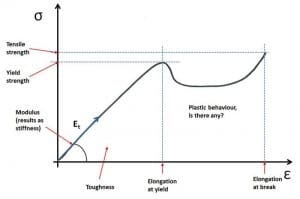

1. Tensile Strength – The maximum amount of tensile stress that a material can withstand before failure through a deformation, rupture or breaking.

2. Elongation at Yield – The ratio between increased length and initial length at the yield point.

3. Elongation at Break – The ratio between changed length and initial length after breakage.

4. Nominal Strain at Break – Tensile strain at the tensile stress at break.

5. Modulus of Elasticity – The tendency of a material to deform along an axis when opposing forces are applied along that axis. The ratio between tensile stress and tensile strain.

6. Secant Modulus – It is the slope of a line from the origin to any point on a stress-strain curve.

Although the standard testing is conformed to “dumbbell” and “dog bone” shaped materials, here at Impact we have tested materials which are hoop shaped. When performing a tensile strength test to a hoop, it works in a very similar fashion to a standard material test. A “dumbbell” shape is cut into the hoop and is then pulled apart in the same manner as the standard material.

Much of our plastic testing is covered under our UKAS scope of accreditation for laboratory 0402 in line with ISO 17025. Our team boast over 100 years of combined experience in plastic testing and our laboratory has racked up more than 500,000,000 hours of plastic testing data since 2002.

Whether you know exactly what testing you require, or you’re unsure of the right testing route our team of experts are on hand to guide you through the various plastic testing programmes to identify the best one for you and your product. All our testing programmes include full reports including the method of plastic testing and a full analysis of results and further recommendations. All our testing is performed by our expert staff and can be trusted thanks to our UKAS accreditation and 100% independence, while we pride ourselves on offering the best customer experience in the industry.

Impact Solutions

+44 (0)1324 489 182

Website

Email