Students Become Integral to Gratnells Engineering Team

Three Harlow college students joined Gratnells Engineering for work experience in the summer of this year.

They worked in each of the different sections in the factory, gaining an insight into what working life would be like for an engineer, and very quickly it was apparent that they would all make great additions to the team. Sam, Jamie and Thomas were all taken on as apprentices after their two weeks work experience with the agreement that they would finish all of their coursework before they started. Which of course, they did. They have all now been put on a five year plan and passed their probationary period.

Apprenticeships are an excellent way for young people to kick off their career in engineering. It is a great way to gain valuable hands-on experience with the added appeal of earning while learning. From a business standpoint, companies benefit from acquiring STEM talent early and gain the ability to mould raw potential from scratch.

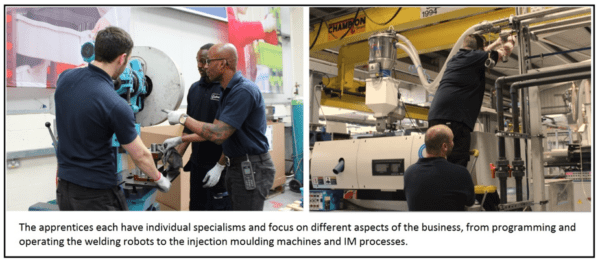

The apprentices each have individual specialisms and focus on different things throughout the factory. Sam chose to work in the primary section where he focuses mainly on programming and operating the welding robots as well as carrying out the quality and safety checks on all machines in his section to ensure they are working correctly.

Thomas and Jamie both chose to work in our injection moulding section where there are 12 machines to keep them busy. They have both completed their robot training and at work focus on things like colour, tool and nozzle heater changes and are involved in all parts of the injection moulding process. Six months in and all the apprentices have completed a crane training course and can now operate the cranes in the factory safely.

“I am really enjoying my time as an apprentice at Gratnells, so far I have gained lots of valuable knowledge and I am keen to know even more about the machines and how they work, the experience has really helped me to mature and know what I want to do in the future” said Jamie.

Phillip McGowan, injection moulding technical manager sees the benefits of the apprenticeship model, not only for students but for companies like Gratnells Engineering.

“Since joining us, the apprentices have settled very well into what is a completely new environment for them. Their constant development is a testament to their attitude and they are learning new skills on a daily-basis. These skills will form the foundations from which they will turn themselves into integral members of the Injection Moulding Department.

Their value in this area is increasing all the time as they develop their knowledge with in-house and external training. I also believe that other members of the team find it rewarding to be in a mentoring role for them, due to their energy and enthusiasm for learning. “

Gratnells Engineering are looking forward to seeing how the boys progress over the next five years, Thomas and Jamie have both been tasked with being able to crane and install an injection moulding tool by themselves on their next birthday and Sam is looking forward to getting involved with the continuous improvement plans.

Gratnells

+44 (0) 1279 401 550

Website

Email