Increase Your Shredder Throughput with Renmar’s New Partner

Renmar is a leading supplier of machinery and ancillaries to the UK plastic processing sector, representing many of the world’s leading brands. They’re delighted to announce an exciting new partnership with ISVE, a prominent Italian manufacturer of specialised shredding equipment.

Established in 1977, ISVE offer one of the widest ranges of both Single and Four Shaft models. All offer superior build quality, use Siemens control systems, and offer extended service life of cutting elements. With every model the dimensions of the final shredded material can be optimised.

As well as having Renmar’s field based service engineers to call upon, shredders can be fitted with a remote access module that also allows the OEM to diagnose any issues.

Single Shaft units employ a hydraulic ram system that directly feeds material onto the shredding rotor. To maximise throughput, the ram utilises a feedback system which continually monitors motor torque levels. This has the additional benefit of reducing the risk of jamming and increasing the lifespan of the cutters.

Other features include:

– High throughputs. Up to 400 kilos per hour, even with the smallest 22 series model.

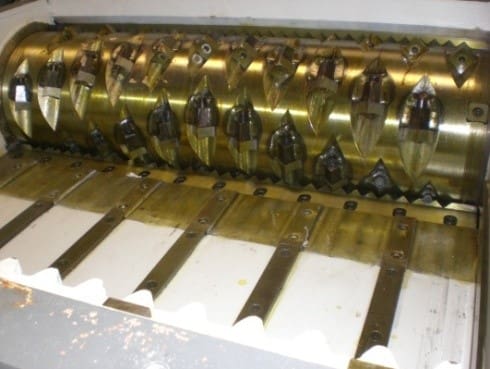

– Rotors are fitted with multiple long-life alloy tools, incorporating four cutting faces. Only one of these tools is utilised at a time and are held within specialised tool holders allowing rotation as they wear.

– Bearings are fully sealed, preventing dust impregnation.

– Belt drive systems minimise mechanical wear and noise levels by reducing vibration.

Four Shaft models are designed to cope with larger items, having cutting chamber sizes up to 1200 x 800mm.

High throughput levels are achieved by using counter rotating ‘hooked’ discs that grab and drive material onto the cutting faces. Key features include:

– Screen size selection from 14 to 35 mm, allowing accurate selection of final material dimensions.

– Product is re-circulated until the correct sizing is achieved.

– Auto-reverse feature prevents blockages and prolongs cutter life, without interrupting the shredding process.

– Easy maintenance of key components.

– Control system allows peripheral devices such as blowers, loaders and conveyors to be easily integrated.

Some unique features of this product range include the option of a small camera close to the cutting chamber, allowing remote viewing via the remote access system.

Combi-System. Four shaft models can be supplied with a directly coupled granulation system. Very large items can therefore be quickly converted into readily useable re-grind in a single operation.

Contact Renmar to discuss how these market leading solutions can improve your process.

Renmar Plastics Machinery

+44 (0) 844 6933225

Website

Email