Plunkett Associates Expands to Offer PVC Mouldings

Plunkett Associates have recently teamed up with a supplier who has been moulding PVC for the last 30 years. He has seen the good, the bad and the ugly within the development of PVC moulding industry, and had the answer to pretty much every question they fired at him…

What’s your experience with PVC (Polyvinyl Chloride)?

I started moulding in 1977 – 40 years ago! Since then I have made pretty much everything from large to small, the easy and the difficult. I’ve also been responsible for around 1.5 million conservatories being built. I love the variety and dare I say, still get a buzz out of those challenging parts!

What are the main reasons for using PVC?

I just think PVC has it all…. It is strong, durable and lightweight and incredibly cost effective. It is also an extremely safe material being non-toxic and fire resistant.

I also love the fact that the parts I produce are uniform and come off the machine the same colour and with the same surface finish whether it’s part number 2 or 20,000. PVC parts retain their colour too and don’t tend to fade like some other materials.

In addition there are no limitations regarding the complexity of the parts that can be produced. The sky really is the limit…

What can PVC be used for?

What can’t it be used for?! One of the most common uses for rigid PVC is pipework – the fact that it doesn’t corrode, and is long lasting, makes it ideal for all outdoor applications. Other uses include the obvious such as windows, doors and conservatories. In fact the construction industry would be lost without it now!

Flexible PVC is used for electrical cables as it is a good electrical insulator. This plus the fact that it is non-toxic means it is safely used within the medical and food industries for a huge variety of applications.

Why do some moulders shy away from using PVC?

When I first started moulding with PVC there were problems and some moulders still seem to struggle to use it as a material. I worked with it and developed a team of toolmakers and between us we learnt to overcome the initial teething problems.

As technology progressed it became easier and now it is my material of choice. You have to have faith in the design and your toolmaker and I am lucky as I have both of those. Between Plunkett Associates, myself and the toolmakers, we should have about 200 years of experience between us so I am pretty confident that we will be able to take on almost anything! (or in really extreme cases know when to step back!)

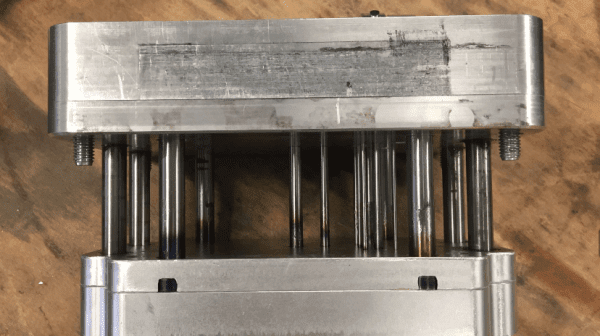

Do I need specialist tooling to mould in PVC?

The answer to that one is no more so than for any other material. My many years of experience stand me in pretty good stead to predict how it may react to particular alloys, and why and when to look after the tool.

Can you source the appropriate tooling?

Naturally, experience is the key here. I know some pretty special toolmakers that I have worked with for a long time who, again don’t worry about working with PVC. Between us we work out the best solution for the clients requirements.

What size parts can you produce currently?

With the machines I have at the moment, I can produce parts up to about 200g (about 300mm in length). Because I work so closely with the toolmaker and the guys at Plunkett’s, turnaround time is as quick as it can be.

Obviously high quality parts are a must, but if the design is right and speed is of the essence, then of course we can get parts made as soon as. (This is nearly always governed by the toolmaking and part complexity).

Why have Plunkett Associates teamed up with you?

Tim was saying they’ve had many enquiries over the years for PVC parts but often people don’t realize the benefits or the many applications for the material. The fact that PVC is often overlooked and yet so price competitive in comparison to other commonly used materials is criminal really. As a result, Tim felt it was time to strengthen Plunkett Associates capability in this area in order to be able to service clients needs – and then they found me!

What next?

Contact Plunkett’s initially and they will take it from there.

Plunkett Associates

01452 386608

Website

Email