Top Five Reasons to Visit Bausano at K 2022

Bausano will be showcasing innovation and expertise at K 2022 with the extrusion specialists shining the spotlight on plastics regeneration, and energy efficiency. K visitors will not want to miss this unique technology. Here are the top five reasons to stop by the Bausano stand…

1. Experience ground-breaking plastic waste regeneration technology

Visit the Bausano stand (Hall 16, Stand B70) and get the chance to engage with the new series of E-GO R single-screw extruders, and find out how they are designed for regenerating both in-house industrial waste and domestic post-consumer waste from washing lines. Thanks to the ground-breaking E-GO R technology, even highly contaminated plastics, such as HDPE residues from containers can be fed back into production processes.

2. Worldwide patented technology offers customers multiple benefits

Bausano will be exhibiting their twin screw technology (equipped with the worldwide patented Multi-Drive System) for the regeneration of plastics. This exclusive technology offers solutions for producing granules from recovered rigid and flexible PVC. The extrusion lines of the MD NEXTMOVER series can be fully customised even with additional components and stand out for being flexible when it comes to recycling various types of PVC waste, according to the level of contaminants, percentage of humidity and grind size.

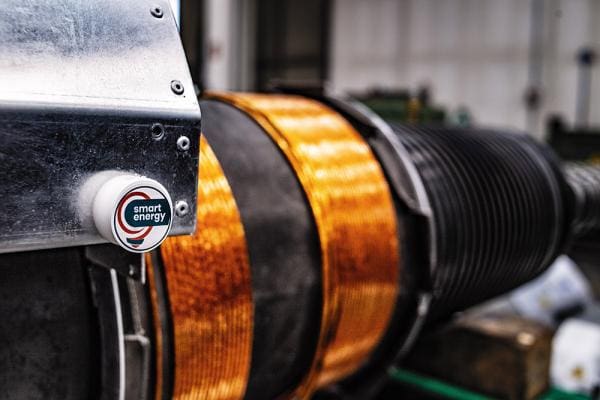

3. Discover how the Smart Energy System offers outstanding energy saving potential

Bausano will be showcasing The Smart Energy System, a patent pending integrated thermoregulation system which provides numerous benefits, including uniform distribution of heat and a lower coil surface temperature, rapid heating up to 250°C and high precision temperature control. Moreover, thanks to its innovative internal design, the cooling airflow is channelled directly onto the plasticising barrel for faster cooling compared to resistive systems.

4. Expert Talks to help improve your production

On top of providing opportunities for technology demonstrations, Bausano experts will be on hand to provide consultations. The expert team includes:

Marco Masiero – RECYCLING and Post Industrial Re-process Specialist, will help you discover how the use of recycled raw materials will reduce procurement costs to a minimum, leading to immediate savings within the entire production system.

Massimiliano Fenili – PIPE Extrusion Design and Process Expert, will show you how automation and line synchronisation can increase pipe quality and reduce production costs.

Alessandro Ruotolo – SCREWS Designer and Process Engineer, will provide key answers to avoid inefficient solutions that can lead to prolonged downtime, poor quality products and lost profits.

Fabrizio Rampone – COMPOUNDING Specialist & Extrusion Technician, will share the information required to understand and prevent instabilities paired with the interactions between the extruder configuration, process parameters and response variables.

5. Sustainable technology is at the heart of bausano’s innovations

‘Given that virgin raw materials are becoming less readily available and environmentally sustainable, the solution is to switch to a circular economy’, says Clemente Bausano, Vice President of Bausano. He also adds, ‘In fact, by using recycled raw materials, procurement costs can be minimised, which translates into immediate savings for the entire supply chain. At Bausano, however, we believe that plastics from post-industrial or post-consumer waste materials should be fed back into the production cycle: this is necessary not only from an economic perspective, but also, and especially, for ethical reasons in order to protect natural resources and the sustainability of the entire supply chain’. He then concludes: ‘This is why we strive on a daily basis to design extrusion lines that are increasingly eco-friendly and as efficient as possible’

Read more from Bausano here.

Bausano

+44 (0) 7815 921 951

Website

Email