3DPRINTUK Case Study: Subsea Measuring Equipment

3DPRINTUK are very proud to be chosen as an SLS supplier for Kongsberg Maritime, to manufacture a 3D-printed instrument used for underwater positioning and mapping.

Overview

Kongsberg Gruppen (KONGSBERG) is an international, knowledge-based group that supplies high-technology systems and solutions to customers in the oil and gas industry, the merchant marine, and the defence and aerospace industries.

Kongsberg Maritime delivers products and systems for positioning, navigation, automation and handling systems to merchant vessels and offshore installations, as well as products and systems for seabed surveying and monitoring, and for fishing vessels and fisheries research. KM is a market leader in these areas.

Project Specifications

CAD Design: Provided by Kongsberg

Material: SLS Nylon

Polishing: YES

Dyeing: YES

Finishing: N/A

Dimensions(mm): Finished item made up of several parts

Project cost: NDA

Details

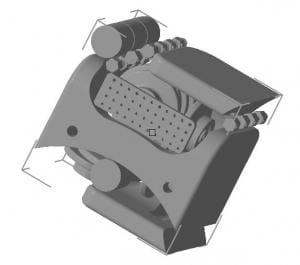

This picture above shows a nest of parts made by KM and is an excellent example of how nesting parts can save you money on part costs.

Using our XYZ pricing structure, it can be far more cost-effective to nest multiple parts together in the smallest possible area. All the empty space surrounding your part that is not being used can be filled with other parts and printed at no extra cost.

SLS allows you to brand your parts and add custom part numbers; and even more beneficially to a project like this, you can combine multiple functions into one body.

Robert Kovacs, Senior Subsea Design Engineer at Kongsberg Maritime, commented: “This part is a multi-functional product chassis, not just a simple bracket to join two things together. It has nifty features, and clever functionality that we would not get from a similar metal or injection moulded plastic part.

“By deciding to 3D print this pivotal part in a new design right from the word go, we were able to shrink the size, while integrating features and functionality that are simply not available through other manufacturing methods.

“The finished product is a scientific subsea instrument for underwater positioning and mapping.“

About 3DPRINTUK

3DPRINTUK is an SLS 3D printing service, specialising in low volume batch manufacture of plastic parts using state of the art 3D printing systems. 3DPRINTUK offer an express turnaround and accept orders from 1 to 10,000 parts, with no tooling costs. You can upload the .stl file for your part online, for a free automatic quote, or use the online pricing calculator to estimate the cost of producing your parts before you even start designing.

Find out more about 3DPRINTUK by visiting the company website, and for more case studies like this one, visit the case study archive.