3DPRINTUK Showcasing Versatile 3D Printing Service at TCT 3Sixty

3DPRINTUK, the UK’s leading specialists in low volume polymer part production using 3D printing, is exhibiting on Booth B65 at TCT 3Sixty in Birmingham, 8-9 June 2022. During the last decade, 3DPRINTUK has established itself as a leading provider of 3D printed polymer parts using powder bed fusion (PBF) processes, specifically SLS and MJF, and members of the 3DPRINTUK team will be on hand at the event to discuss ways in which 3D printing can be used as a viable production process for a variety of applications.

Nick Allen, MD at 3DPRINTUK says,

“We will be at TCT 3Sixty once again demonstrating to attendees how we have refined our internal processes to ensure that we retain our number one status in the UK for the manufacture of prototype and production parts and components using 3D printing. From our front-end automated online ordering system, through the use of 3D printing technologies to make parts, and then onto a full range of post-processing technologies, we have invested in best-in-class solutions, which when combined with our unrivalled in-house expertise mean that our customers get the highest quality parts cost-effectively and in a timely fashion.”

3DPRINTUK is working at the vanguard of the 3D printing sector and is routinely proving the viability of PBF 3D printing technologies for the production quantities of plastic parts and components. Attendees at TCT 3Sixty will be able to see examples of parts made using various materials and having been finished with a variety of post-processing technologies at the 3DPRINTUK booth. The 3DPRINTUK team also invite attendees to bring along details of specific applications so that they can assess how 3D printing can be beneficial in terms of time-to-market and cost competitiveness.

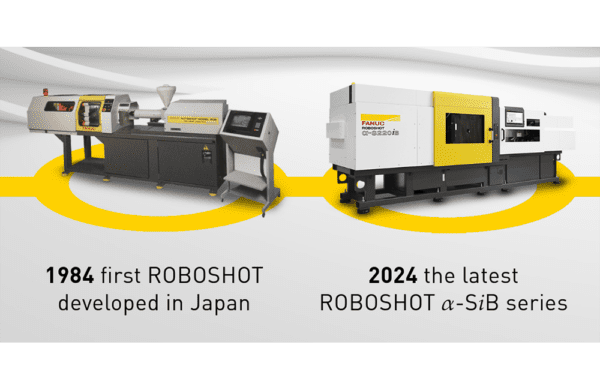

Allen continues, “When working events like TCT 3Sixty, we have a valuable opportunity to show just how versatile and compelling 3D printing is as a prototyping and production technology. For production, 3D printing exhibits a number of advantages when compared to legacy processes such as injection moulding, perhaps the most important being the added flexibility it allows in design. 3D printing can make components of a geometric complexity either impossible or disproportionately expensive to achieve using injection moulding, and so stimulates innovation and allows design engineers to continually push the envelope.

“3D printing also promotes what can be called the consolidation of complexity, the technology combining parts and features in one build that would otherwise have to be post-processed or assembled using conventional injection moulding and allied technologies. Also, 3D printing requires no tooling and is agile which facilitates quick production turnaround. With 3D printing, part cost is not connected with part complexity. As soon as complexity is introduced to an injection moulded part, the requirement is for more and more expensive mould tools, which leads to an exponential increase in costs until part production is no longer viable. At 3DPRINTUK we have the knowledge and expertise to exploit all of these technological advantages on your behalf, and would be delighted to discuss opportunities with you at the event.”

3DPRINTUK operates from a 10,000 square feet HQ in London, which houses a growing fleet of SLS and MJF machines, as well as vibro polishing, shot peening, and colour dyeing services. Today, the company is renowned as a leading expert in the use of PBF 3D printing technologies for prototypes and small- to medium-sized production runs. The company is able to offer a reliable and flexible manufacturing service that bridges the gap that exists between prototyping and injection moulding in a highly efficient way, overcoming the limitations that alternative processes such as CNC machining and vacuum casting present.

3DPRINTUK

+44 (0) 208 692 5208

Website

Email