3DGBIRE Announces Partnership with miniFactory

3DGBIRE is pleased to announce its partnership with miniFactory, expanding its portfolio of high-performance 3D printing systems for industrial applications.

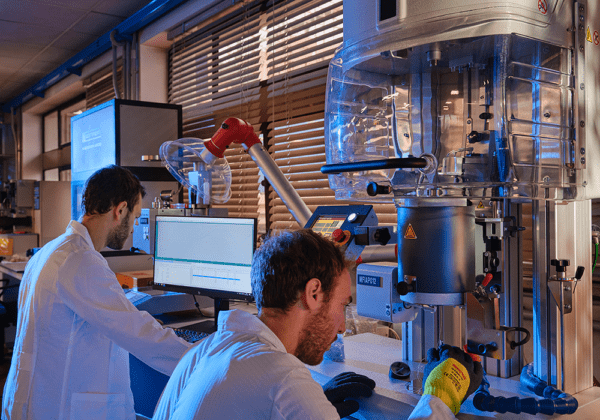

MiniFactory is an industrial 3D printer manufacturer driven by a passion for high-performance polymer 3D printing and the best results for industry-class 3D printed parts. 3D printing with

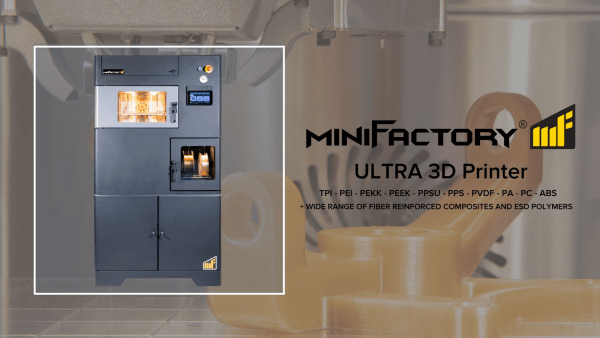

polymers like PEEK requires a high melting temperature and temperature-controlled environment. These requirements make it necessary to specifically manufacture 3D printers with such capabilities. MiniFactory has introduced the new miniFactory Ultra – the latest addition to the family of PEEK 3D printers!

The miniFactory Ultra 3D printer has an advanced heated chamber up to 250°C, which unlocks the whole material range for you. From commodity and engineering polymers all the way up to the most demanding high-performance polymers and composites. The material range is many times wider than in ‘closed systems’ or in the systems with lower chamber temperatures. Extremely high temperature in the chamber unlocks the widest material range on the market and ensures ultimate strength for printed parts. High-performance polymers are extremely sensitive to humidity; this is where Ultra’s heated filament chamber ensures the optimal condition for your materials.

The miniFactory Aarni process monitoring system is the top layer in high-performance polymers and is a pioneer in the field of FFF manufacturing. You can connect Aarni to your Ultra 3D printer to have industry-level quality control for your 3D printed parts.

Main features of the miniFactory Ultra include:

- Heated chamber: the Ultra’s build chamber can heat up to 250°C to enhance layer adhesion and mechanical strength while avoiding warping and mechanical stress issues.

- Heated filament chamber: can heat up to 120°C.

- Dual extruder: dual extrusion enables users to 3D print with two different materials or 3D print two identical parts simultaneously. The nozzles can reach up to 480°C.

- Intuitive touchscreen: this PEEK 3D printer’s 7-inch touchscreen provides valuable monitoring information and control over the 3D printing process.

- Automated post-processing: miniFactory’s Ultra 3D printer features integrated annealing of parts to improve their physical properties.

- Carbon filter: the Ultra boasts an active filter to reduce the emission of potentially harmful particles.

- Open material system

Common applications for ultra polymer 3D printing

Functional prototyping: The innovative technology of Ultra 3D printers provides engineers an opportunity to test the products with authentic materials in a real operational environment and bring the products to the market faster and more cost-effectively than before. For the first time in this price range, materials such as ULTEM 1010, ULTEM 9085, PEKK, PPSU, PA CARBON, PEEK are 3D printable with an optimal temperature process, whereupon the 3D printed objects have the optimal mechanical strength with minimum dimensional changes.

End-use-parts: Ultra 3D printer offers an opportunity to produce high-quality mass-customised parts and various small series productions reliably. The parts can now be produced in-house cost-efficiently and quickly.

Tooling: With the chemical resistance, mechanical strength and high-temperature resistance, the tooling solutions can be made even for the most demanding situations. Small changes to the demand can be reacted with new design revisions in the model and reprinted quickly with cost-effective production.

Pricing and availability: The miniFactory Ultra launched on October 4, 2021. Prices are planned at £50,500.00; however, this varies with each bundle.

Visit www.3dgbire.com or use the contact details below to book a demonstration with 3DGBIRE and learn more about the new miniFactory Ultra 3D printer.

3DGBIRE

01257 228411

Website

Email