Requirements for the Production of Tethered Caps

The EU directive 2019/904 of the European Parliament sets new requirements for the production of tethered caps – read the details here.

Tethered caps are caps which remain firmly attached to the bottle after opening and during the product’s service life or life cycle. The relevant part of this EU regulation for Caps & Closures production reads:

“Plastic closures and lids used for beverage containers are among the single-use plastic items most frequently found as litter on the beaches of the European Union. Therefore, the placing on the market of single-use plastic beverage containers should only be allowed if they comply with certain product design requirements in order to significantly reduce inputs of plastic container closures and lids into the environment. For beverage containers that are both single-use plastic articles and packaging, this is an additional requirement to the basic composition, reusability and recoverability, including recyclability, requirements for packaging set out in Annex II to Directive 94/62/EC.”

Which caps are not affected by the EU regulation on tethered caps?

This Regulation shall apply to the caps of all beverage containers up to a capacity of 3 litres, i.e. containers used to hold liquids, such as beverage bottles, including their closures and lids and composite beverage containers, including their closures and lids, but not:

Glass or metal beverage containers with plastic closures or lids

Beverage containers intended for liquid foodstuffs for special medical purposes

The legal foundations based on this regulation must be created in the EU member states by 31 July 2021, and the entry into force of the legal and administrative regulations is scheduled for 3 July 2024 at the latest. Read the next paragraph to find out what requirements this EU regulation places on tethered caps in detail.

Basic requirements for tethered caps

The requirements for the design and function of tethered caps resulting from this regulation are currently still being defined and at the moment can be summarised as follows:

- The closure must be compatible with existing preform designs, openings and thread types.

- Impact on the end customer should be kept as low as possible, i.e. comfort of use should not be reduced.

- Closures are compatible with existing filling equipment.

- Closures are connected to the container throughout the entire product life cycle until recycling.

- Materials for the tethered cap are not changed.

- Impact on existing production lines should be minimised and output should not be reduced.

- 15 times opening and closing of the cap without loss of function must be guaranteed.

- The connection between tethered cap and the container must withstand at least 25 N tensile force.

Ivica Puskaric, Sales Director Packaging ENGEL Austria says, “The new requirements for beverage closures necessitate fundamental changes in production. We are actively working on this topic and look forward to advising you.”

Strategies for the production of tethered caps

Currently, two main production concepts exist to achieve the new requirements for the production of tethered caps:

- With the “slit concept“, the cap is cut after injection – this has the advantage that the current tools can still be used but requires an additional work step in the production and significantly restricts the design scope of the tethered caps.

- With the “bridge concept“, a band is injected along with the cap, which requires new tools. The advantage of this concept, however, is that no additional work step is required afterwards, greater freedom of design is possible for the caps and the injection-moulded connection between the cap and the band can withstand higher loads.

Tethered Caps Design Concepts

There are currently two dominating variants in the design of tethered caps:

- The “lasso design” refers to caps that are connected to the bottle with a two-part band. The cap is connected to the upper band and the bottle to the lower band. This design is relatively easy to implement with existing tools, usually only the sliders need to be reworked.

- The “hinge design“, on the other hand, allows the permanent connection of cap and container by means of a hinge, which optionally also allows the cap to be fixed in a defined position. The use of existing tools is practically impossible.

What impact does the Tethered Caps Regulation have on production?

Due to the high demand in the market, many manufacturers are expected to start with the Lasso solution first as the Hinge design requires high investments in both time as well as financial terms due to the need of a new mould. In addition, the hinge design may require adjustments to the filling line and the feeding of the tethered caps, resulting in further costs.

As a trend for the future, it is expected that in the course of the changeover to tethered caps, many producers will consider switching from 1810/1811 cap types to 26mm caps. The advantage here is a possible reduction in cycle time and material usage. For the injection moulding machine, tethered caps require higher injection speeds and increased injection pressure, as the required cavity internal pressure will tend to be higher. The reason for this is the changed filling behaviour with an increased number of filling points on the TE belt. The necessary clamping force, on the other hand, will not increase with a change to a 26mm closure.

What requirements does the Tethered Caps Regulation place on injection moulding machines?

For the injection moulding machine, tethered caps require higher injection speeds and increased injection pressure, as the required cavity internal pressure will tend to be higher. The reason for this is the changed filling behaviour with an increased number of filling points on the TE belt. The necessary clamping force, on the other hand, will not increase with a change to a 26mm closure.

Read more news from ENGEL here.

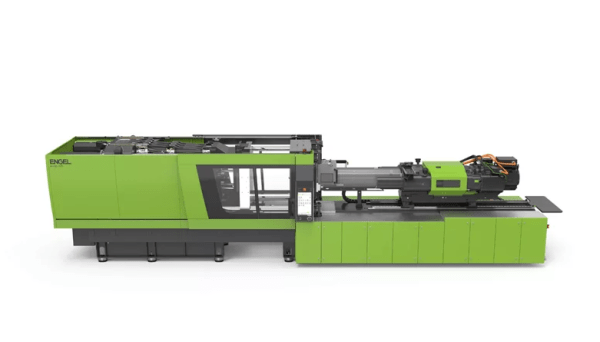

ENGEL

+44 (0) 1926 335000

Website